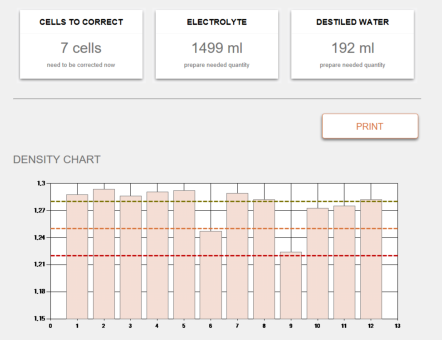

Electrolyte Regulation System

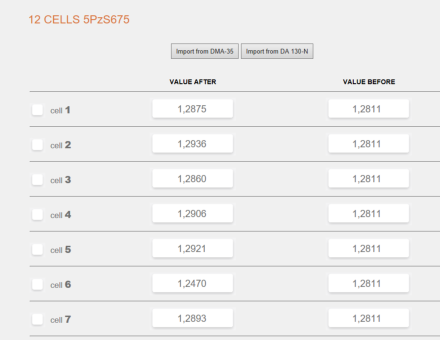

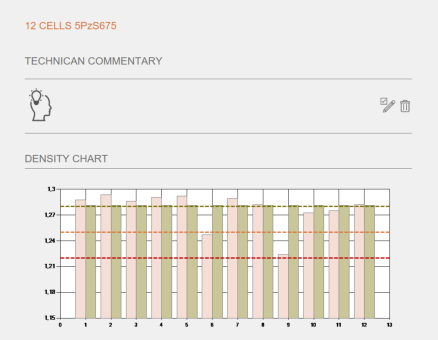

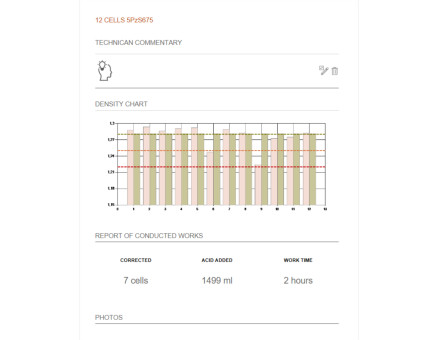

50% of the success of battery regeneration depends on the regenerator and the remaining 50% on the correct levelling of the acid density level in the cells. For batteries with an air system, the adjustment of the electrolyte is even mandatory.